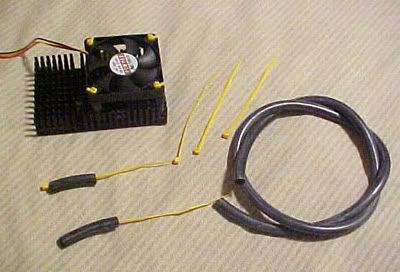

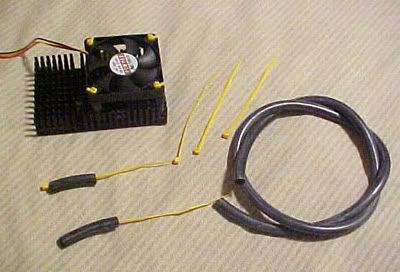

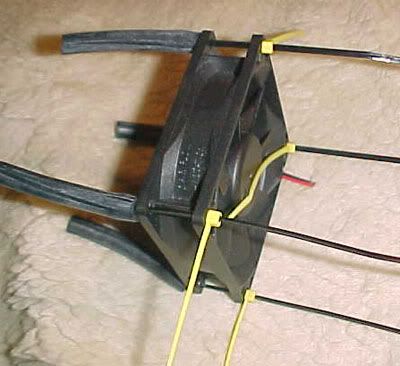

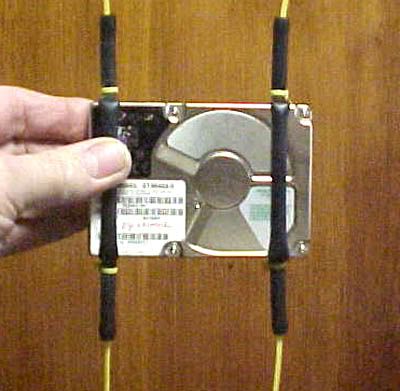

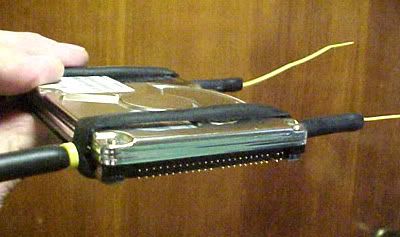

Zip-Ties and vacuum hoses both come in many sizes. I've never seen weight/strength ratings for the hose.....but they probably exist. For a 3.5" drive you might want to use the next larger hose (only slightly bigger). Zip-Ties do come with weight ratings.

At Home Depot that 3" Zip-Tie is rated for 15lbs. There is also a small Zip-Tie with a "military spec"......that one is rated for 75lbs. I seriously doubt you'll ever break one in a computer application. The larger sized Zip-Ties could pull a car.

The only thing to be aware of is to use the same type/brand Zip-Tie to attach together. If you mix types, they might not hold well. I'd buy the vacuum hoses at an auto parts store. It comes in bulk....so just get a few feet of each small size,

Pulling a Zip-Tie into a vacuum hose requires two hands....you hold one end of the hose with one hand, pull the Zip-tie into the hose with a pliers on the end of the Zip sticking out. Not too hard......

There are countless uses for these things.....experimentation will no doubt find many more than what I've shown here.

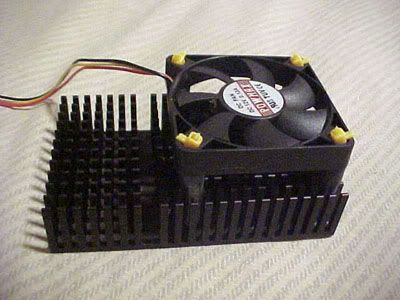

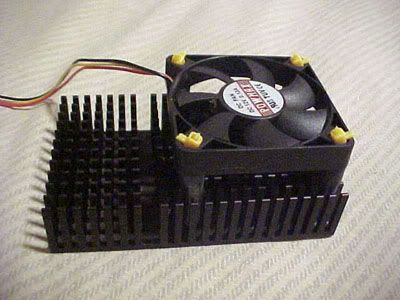

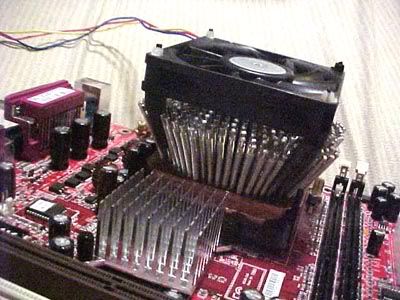

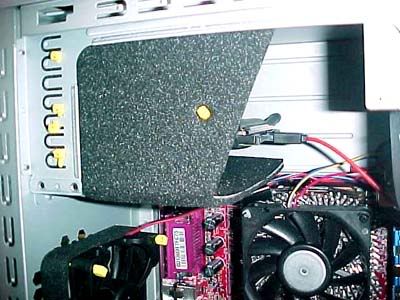

Here's a 120mm Yate Loon mounted within 1/8" of a Ninga using vacuum hoses and zip-ties. I wrapped plastic tape around the four hoses to construct a short enclosed duct to the case.