The case as it was.

Some parts.

I blow at soldering. It’s a good thing steel wool cleans it up nice.

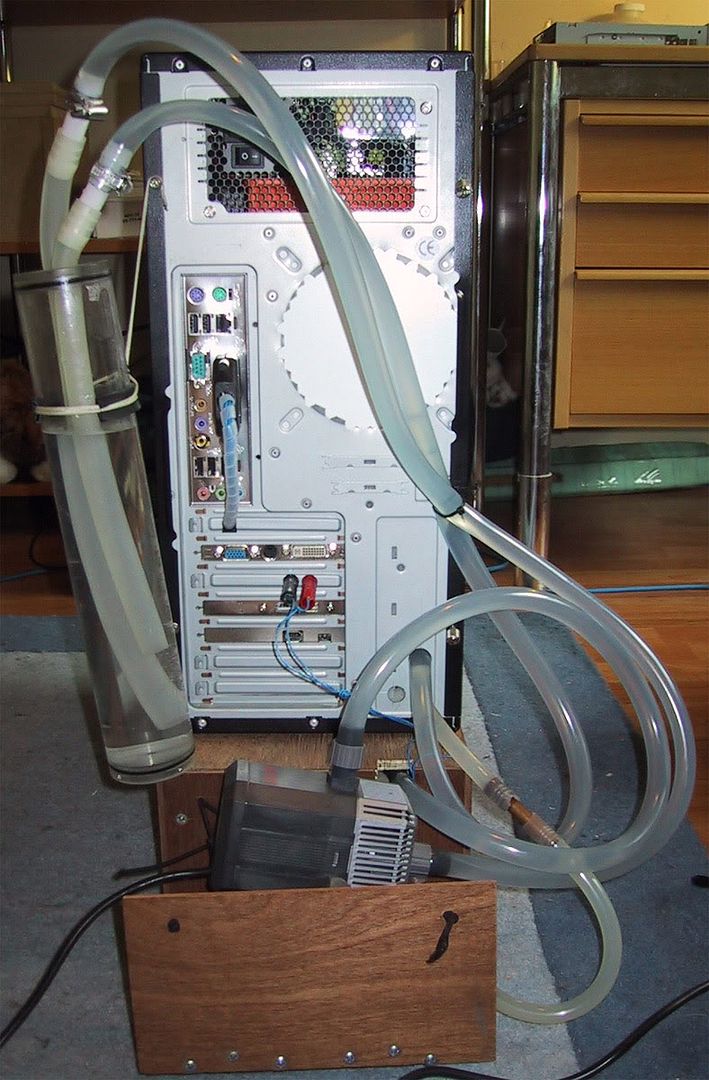

The finished product.

Pressure testing is fun!

Assembled.

The rubber strap was a last minute thought, but a good one, I think.

I took the opportunity to duct my PSU out the back.

On the whole, I’m pretty happy. My HD temps dropped by 10-15C and idle noise is absent, although seek noise is slightly louder (the were mounted the standard way in an Antec BQE). I had a small leak when I first re-assembled it, but I got it sorted out at the cost of my WAN card. That’s okay. It sucked anyways.

I may cover the HDs with something more to quiet them further later. I'm happy to answer any questions that anyone might have.